2 Applications Of Electron Beam Welding

Metal 3D printing equipment. Electron beam welding applications 1.

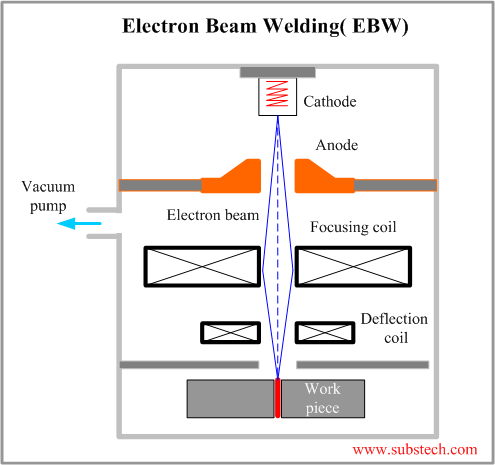

Electron Beam Welding Ebw Substech

Those with different melting points and thermal conductivities.

2 applications of electron beam welding. Electron Beam welding is a fusion welding process. Micro-electronics Computer nautical navigational instruments communication equipment etc Optics Projection lenses for TV and computer monitors etc Cutting tools Jewelry diamonds metal parts with intricate shapes that prevents the use of conventional cutting methods. It is used to weld electronic connectors in.

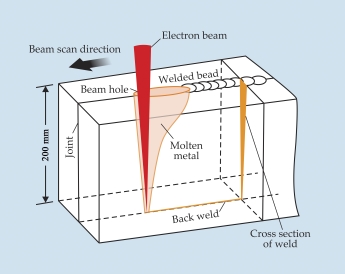

Three major applications of electron beam welding are. Welding is essentially performed in a vacuum high-vacuum welding and is characterized by minimal distortion for applications from thick to thin plates and even detailed welding. Besides the ability to weld thick material to thin material electron beam welding also allows joining of dissimilar metals ie.

Automobile aerospace medical and other industrial parts which require relatively low distortion are amenable to electron beam welding technology. The electron beam welding EBW and laser beam welding LBW processes are high-energy density welding processes that offer several possible advantages including low welding heat input high weld depth-to-width ratio narrow heat-affected zone HAZ and reduced distortion. EBW is often performed under vacuum conditions to prevent dissipation of the electron beam.

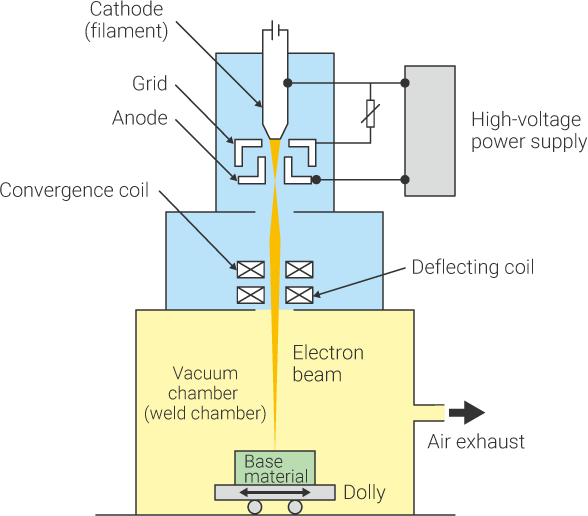

However since electron beam welding is generally performed with the object of welding entirely put in a vacuum chamber high welding cost becomes a problem. It is used in aerospace industries and marine industries for structure work It is used to join titanium and its alloy. Electron beam welding EB Welding is a fusion welding process that uses a beam of high velocity electrons to produce a weld.

As a result this thermal energy melts the metal pieces and molten parts of the metal are joined together. Electron beam welding process is mostly used in joining of refractive materials like columbium tungsten ceramic etc. The electron beam eb welding process is used in a variety of industries.

The workpieces melt and flow together as the kinetic energy of the electrons is transformed into heat upon impact. During the process the kinetic energy of highly accelerated electrons due to the influence of anode is converted into thermal energy. This type of welding is generally used in automobile industries for connecting gears transmission systems.

Some combinations which are unweldable by other processes are thus readily electron beam welded. Applications of Electron Beam Welding It is used in aerospace industries and marine industries for infrastructure work. We work on the design of electron guns that generate high power beams that are used in welding and additive manufacturing ie.

This type of welding is widely used to join gears transmission system turbocharger etc. In response to this demand a local vacuum slide sealing type electron beam welding machine was developed and applied for the vacuum vessel of the fusion experimental device JFT-2M outside diameter 35 m. What are the limitations of electron beam welding.

It is used in. A brief look at the application advantages of EB Welding. This involves simulation engineering design build and commissioning of.

Electron beam light beam welding is a welding method based on a principle of electrons emitted in a vacuum tube or Braun tube. Applications range from fully automated high productivity and low cost automotive in-line part production to single part batch processes in the high-cost aircraft engine industry at the other end of the industrial spectrum. Electron-beam welding EBW is a fusion welding process in which a beam of high-velocity electrons is applied to two materials to be joined.

Electron Beam Welding Applications AEROSPACE POWER GENERATION DEFENSE AUTOMOTIVE OIL GAS ELECTRONICS MEDICAL. Which are used in missiles. EBM is applied to join titanium and its alloys.

The applications detailed here require welding powers of a few hundreds of watts to tens of kW. The electron beam group at TWI develops electron beam equipment and processing for industrial companies.

Electron Beam Welding Wikiwand

Pdf Electron Beam Welding Techniques And Trends Review

Electron Beam Welding Principle Working Equipment S Application Advantages And Disadvantages Mech4study

Electron Beam Welding Advantages Disadvantages Ebpglobal

The Electron Beam Welding Process Explained Ebpglobal

What Is Electron Beam Welding Engineer S Academy Youtube

Electron Beam Or Laser Beam Welding

How Electron Beam Welding Works Explained In Detail Pdf

Principles Of Electron Beam Welding Electron Beam Welding Automated Welding Basics Keyence America

Electron Beam Welding Advantages Disadvantages And Application

Electron Beam Welding Process Applications And Equipment Ptr Precision Technologies Inc

Posting Komentar untuk "2 Applications Of Electron Beam Welding"